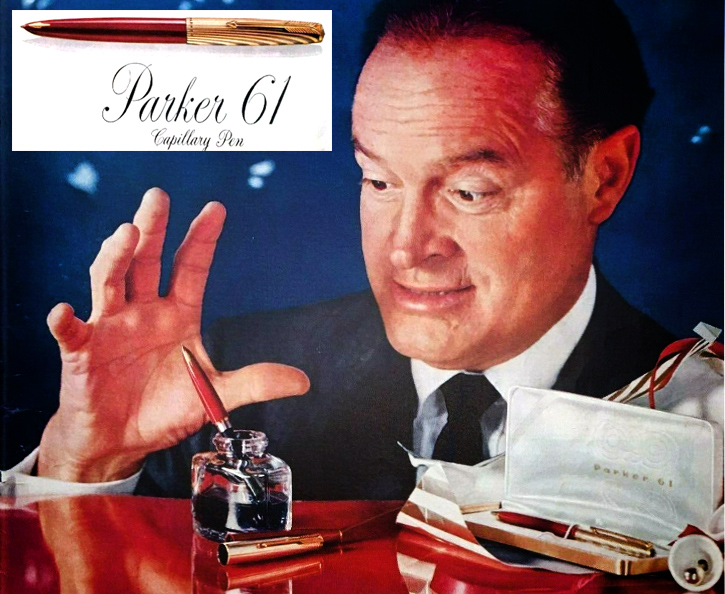

The magical Parker 61 fountain pen

Like most other pen companies, Parker had been working for decades to find the perfect filling system, and when the Parker 61 pen was finally introduced in 1956, it was truly as otherworldly as it was initially advertised. It had many features in common with the then predominant Parker 51 fountain pen, but it was thinner and, most importantly, it filled itself. No one knew how it worked, but it worked.

Until the Parker 61, all pens had some sort of mechanical filling system. In the old days, it had to be filled with an eye dropper or syringe. Most required winding, pushing, pulling levers, pistons or filling buttons. The Parker 61 had no such thing, just a mysterious cylinder with a few tiny holes at the end. All you had to do was unscrew the back and put the pen in the bottle for thirty seconds and the pen would fill with ink. How much is more about that later.

With the launch of the Parker 61, the public was enchanted by a new pen that didn't require much effort to fill. The ink is drawn through a Teflon-coated barrel with a capillary pack that automatically draws ink into the pen.

There were many different solutions for keeping the hand clean. The most successful up to then was the Sheaffer Snorkel, introduced in 1952. This used a kind of syringe under the ink dispenser which could be inserted into the ink and then screwed back into the pen after filling. It was not (in all cases) necessary to wipe off the stained pen tip. Parker 61 pens were made at a time when very few people changed ink colour. Therefore, this pen was more parktic for those who always used the same colour.

In an interview with Pen World in 1989, Don Doman, the legendary designer who designed the Parker 61 and many other Parker pens, revealed that Parker received many complaints during the 51 era about the hidden nib, which made it difficult to hold the pen accurately.

Don Doman found a simple and attractive solution to the problem. He proposed an inlaid arrow on the grip part, directly above the nib.

Initially, the plan was to simply glue the arrow to the body, but Doman argued that the arrow would then fall off too easily. He wanted the arrow to be flush with the surface of the section. The engineers argued that the casting process would be too expensive and cumbersome, but Doman insisted.

Of course, every Parker 61 owner today is aware that arrows fall off (and mostly disappear) all the time, even when the arrows are molded into the plastic.

If Doman had not insisted on the countersunk version, few arrowed Parker 61s would have survived at all. This arrow setting was later adopted by the Chinese, but they fixed the arrow to the pen body a notch more permanently.

Despite the fact that the nib ultimately consisted of few parts, the production costs were still high compared to the benefits. Although the filling system had no moving parts, the user still sometimes had to wipe the barrel after filling, and since most users did not want to bother keeping the ink storage device clean, they rarely washed or rinsed the ink, so it often ended up clogging. Despite a sustained publicity campaign in Life Magazine and the Saturday Evening Post, Parker was eventually forced to stop further production and replace it with Parker's aerometric (pump) technology.

Measurements

Tompens Laboratories calculated how much ink the Parker 61 pen could actually absorb. First, the pen was completely filled with water (de-aerated under water) and then its weight was measured. Then I weighed it again when completely dry. The theoretical capacity of the pen is 1,391g water.

I then immersed the pen in water for 60 seconds to a depth of only 5 mm for the targeted capillary action. It absorbed +0.643g of ink. After the measurement I dipped the tip in ink. It managed to absorb another 0.019g of ink. I then dipped the suction device in water again. Only 0.012g extra was absorbed. After about 10 minutes I repeated again (another +0.01) and reached the maximum. The pen was able to absorb 0.684g of ink. This is slightly less than half of the theoretical capacity. A normal parton has 0.8g of ink. That means that the pen can absorb almost one cartridge of ink. Note that if you dip the suction mechanism into a higher ink column (30 mm), it will suck 1g of ink in 45 seconds in the first round, or just over a cartridge.

You can buy the pen here.

P.S. By the way, the fountain pen in the test is made in Denmark. This is proven by the Carl Olsen stamp clearly visible on the side.